Australian warehouses and distribution centres (DCs) are under pressure like never before in efficiently storing goods and distributing goods to customers on time and in the right condition. Meeting increasingly disparate delivery schedules and stocking a wider range of SKUs to accommodate changing consumer demands and acquisitions create a range of trying operational issues. While much attention in the industry is given to better management of workflows and people to ensure the ongoing efficiency of the DC, one of the most critical aspects of warehouse operations is how to better utilise available, unused storage space.

Having the right storage solution can not only maximise the footprint and storage capabilities of your DC, it can also deliver greater productivity and avoid major relocation costs if the perception is that you’ve outgrown your current facility. But how can you economically get more out of your available DC space? The answer may be through a raised floor that gives you access to unused overhead space.

Raising the standards in DC storage

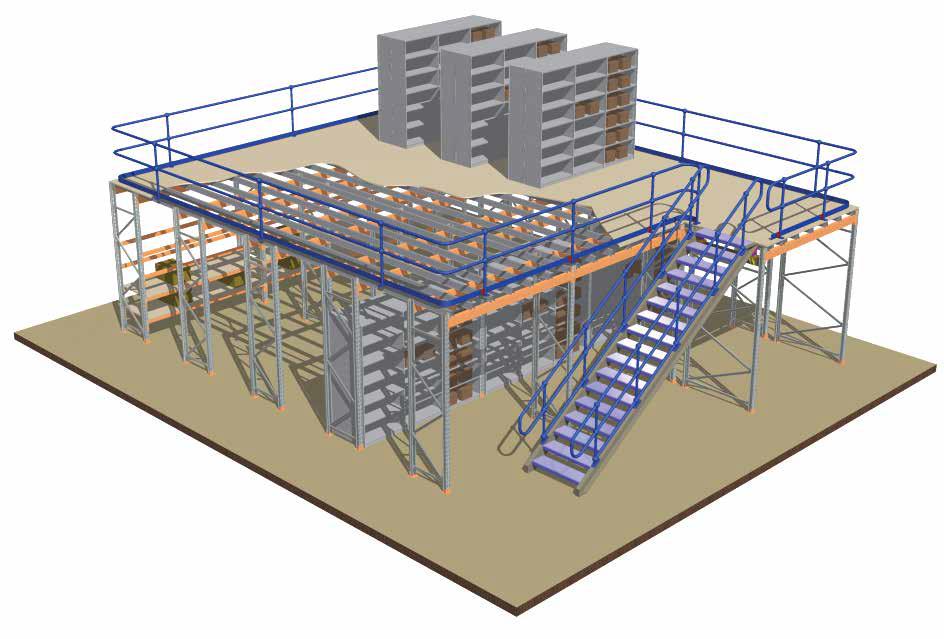

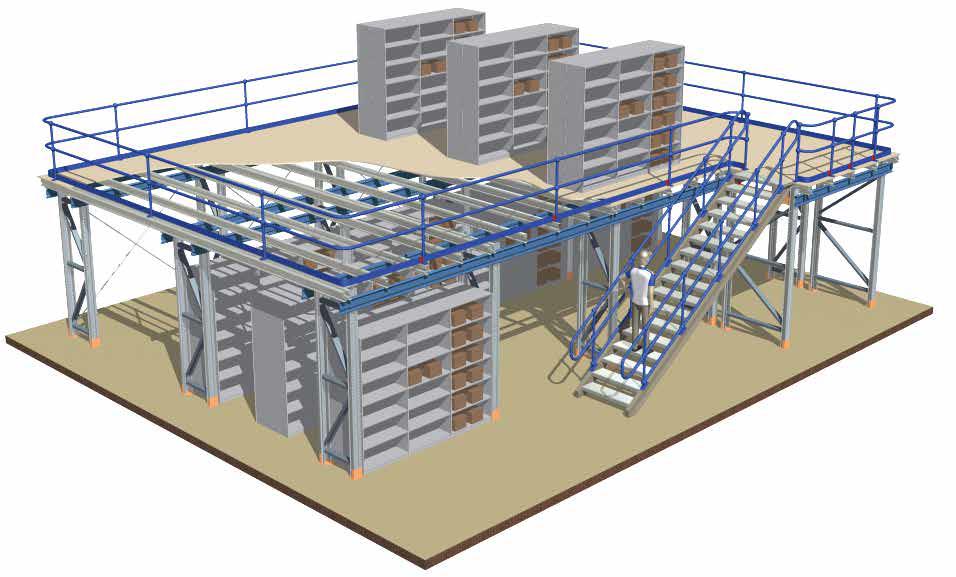

Raised storage areas are cost-effective solutions that can add significantly to the usable floor area in your DC. A raised storage area provides access to an overhead work area without interrupting ground level workflows that can be used for bulk storage, order picking areas or even as additional office space.

Raised storage areas can be integrated with stairs, handrails, conveyors, pallet gates and other lifting and loading devices. They offer virtually unlimited options to utilise valuable overhead space in your warehouse and can seamlessly integrate existing shelving and racking systems, carton-live storage, and heavy-duty shelving. Fire protection equipment such as sprinklers, smoke curtains, and electrical wiring, can also be mounted under the floor.

Medium and Heavy-Duty Applications

A wide range of raised storage areas can be developed to cost-effectively provide more useable space in a DC. Low cost, medium-duty floors can be designed using standard pallet racking components. In heavy-duty applications, structural columns are combined with specialist beam sections which provide the necessary floorspace and load-carrying capability over larger spans.

In a medium-duty flooring system, the floor space is increased by using racking as a fast and inexpensive means of constructing free-standing, raised storage areas. The use of standardised rack components allow quick and easy designs as well as the integration of different shelving and racking systems*.

For heavy-duty raised floors, or cases where larger clear open space under the raised floor or wide aisle space are important, special profile beams can be combined with rack frames or square hollow section columns. This way larger spans can be achieved, delivering more column-free space under the floor, and significantly lowering installation time and costs.

Raised floors can also be designed to be easily moved or modified to accommodate the changing needs of a DC into the future.

Why a Colby raised storage solution?

Designed by Dematic’s industry-leading structural engineers, all Colby raised storage areas are configured to ensure safety, integrity, and compliance, meeting the relevant Australian design standards. Colby’s range of uprights, beams, frames, and connectors are made in Australia from high-quality, high-tensile structural steel. Smart section design including strengthening ribs and reinforcing flanges, also ensure outstanding safety and structural efficiency.

*Subject to any relevant planning approval.